My meads have a terrible track record of being mediocre to rubbing alcohol. Try as I might I just never got the knack of making a good standard mead.

In researching what I may have been doing wrong, I ran across this excellent sticky thread on the Homebrew Talk forums. The secret, they said, was staggered yeast nutrient additions. If you dose it all at once up front, the yeast try to absorb everything at once and end up with unhealthy cell walls that don’t lend to efficient fermentation. It is much better to add smaller doses over first half of fermentation.

Changing the yeast nutrient was also recommended as most yeast nutrients have a healthy dose of inorganic nitrogen in the form of urea. While yeast produce urea as part of their metabolism, a good percentage is reabsorbed by that metabolism within the cells. What cannot be reabsorbed is expelled into the environment. In a fermentation, that environment contains alcohol, which can combine with the urea to form ethyl carbamate. In addition to being a known carcinogen, ethyl carbamate also has a cooling, saline, bitter taste. It’s better to avoid it by minimizing urea and the easiest way to do that is to use a so-called premium yeast nutrient such as Super Food supplemented with diammonium phosphate (DAP).

Super Food and DAP are not all that common at homebrew suppliers so we brought it in special just to try it. There’s no proof like experimental evidence. Let’s ferment something and drink it.

Hypothesis: A staggered yeast nutrient addition will improve the quality of fermented honey (mead).

Prediction: We’ll drink some and find out.

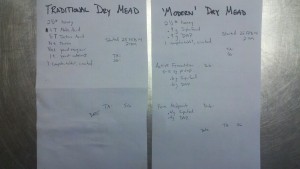

Procedure: Ferment two one-gallon batches of mead, one using a traditional mead recipe, the other using a modern, staggered yeast nutrient addition. As a process curiousity. we’re also omitting the acid additions at the start of the modern mead. We’ll be monitoring TA as fermentation proceeds. If any adjustments are necessary, we’ll do them after fermentation.

Here are the two mead recipes. The gallon jugs were last sanitized with StarSan before they were put away. They got a quick, warm rinse today. Ingredients were added in the following order: nutrients & energizers, honey, water, acid crystals, tannins, campden.

The honey definitely needs to be mixed in manually.

I’ll revisit the post during fermentation to update the chart below. When the meads are ready, we’ll give them a taste test to determine what difference there is. If the staggered yeast addition is indeed healthier for the yeast, we should see a faster drop in SG. The nutrient load and acid additions in the traditional meads may be setting it up for my usual honey alcohol. I’m looking forward to tasting the difference.

Traditional Modern

Date/Time SG* TA SG* TA

25FEB14 1400 1.105 .65 1.100 .13

26FEB14 1600 pitched 2 grams of Lalvin K1-V1116 in each

27FEB14 1030 1.105 .75 1.100 .20

28FEB14 1130 1.096 .83 1.089 .25

01MAR14 1100 1.086 .80 1.079 .22

02MAR14 1100 1.079 .88 1.061 .33

03MAR14 1100 1.072 .90 1.064 .41

04MAR14 1100 1.062 .85 1.048 .38

14MAR14 1030 1.042 .95 1.036 .50

* SG is an converted, uncorrected apparent Brix reading using a refractometer. This conversion becomes less accurate as fermentation progresses.